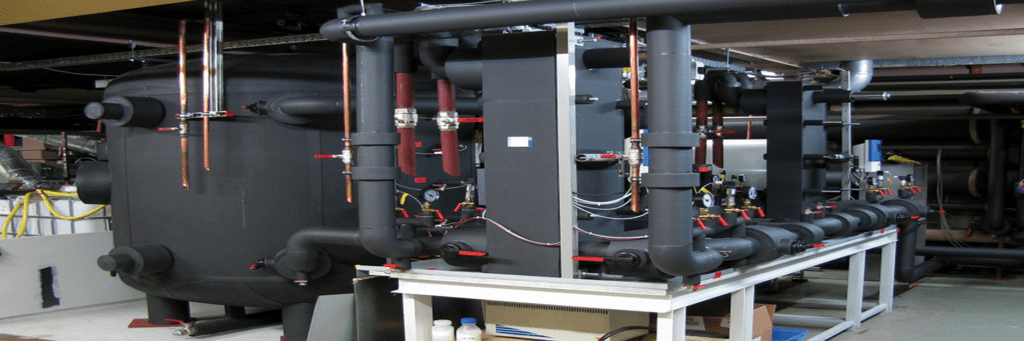

Owing to the immense experience in this domain, Hems Infrawork Pvt. Ltd. is providing Freon Base Cooling System that is widely used to preserve different items on a specified temperature. The provided cold room is highly demanded in agriculture industry due to its prefect result. Our provided cold room is precisely manufactured by utilizing top grade raw material and ultra-advanced technology in conformation to the set industry norms.

Freon (Halocarbons) come in two types, one is methane-based and the other ethane-based. Because of ozone-depletion concerns, methanes are being eliminated from industrial use. As part of the Montreal Protocol, the widely-used halomethane R-12 was phased out in 1995. Ethane-based halocarbon systems are very common today in certain types of processing facilities

Refrigeration System Cost:

In order to make your decision between ammonia and Freon, you run a load calculation for a rule of thumb for costing purposes. If a refrigeration system load is less than 100 tons, you most likely will need a halocarbon system. Of course, halocarbon (Freon) can be used in much larger systems as well, and many choose to do so for various reasons. In addition, installation of a Freon system is usually less expensive than ammonia.

Temperature Requirements:

When choosing between ammonia and Freon, consult an engineer well-versed in the capabilities and limits of each system. Such an expert will consider the volume of product, the type of product your facility produces and the temperature needed to cool the product. For example, Freon is good for cooling up to 60,000 lbs. of meat per hour from 150-degrees Fahrenheit to -10 degrees Fahrenheit. Bread and cheese products have similar boundaries.

Efficiency:

Typically, an ammonia refrigeration system will be more efficient than a Freon system. However, a properly designed Freon system can rival an ammonia system and can even be up to 25-percent more efficient than a poorly-designed ammonia system. This is why it is important to have an experienced engineer design a system to fit your needs.

Flexibility:

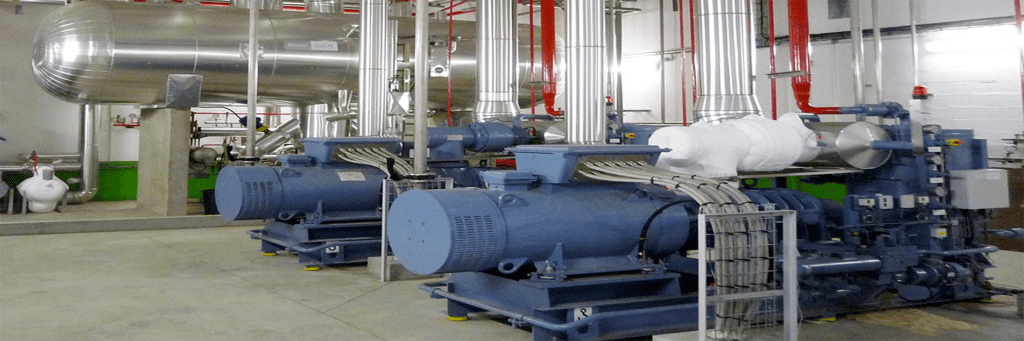

With a rack system (typically used in the grocery industry), a steel rack with a steel frame will contain multiple compressors. If one compressor fails, the others will help carry the load. A remote air-cooled condenser is located outside the building, typically on the roof. This function of this condenser is to propel the heat to the outside environment.

Maintenance:

Unlike ammonia systems, a Freon system can be easily maintained by a well-trained heating and air conditioning contractor.

In our Ammonia Refrigeration Simplified paper we told you everything you wanted to know about ammonia refrigeration but were afraid to ask. But ammonia isn’t the only refrigerant used in food processing, meat, dairy, bakery, and cold storage facilities. Freon is preferred by many processors.

Keywords:

Freon Base Cooling System, Freon Refrigeration System, Freon Refrigeration System Supplier, Freon Chilling Plant, Cold Storage Cooling System, Freon Base Air Conditioning, Freon Cooling System, Cold Storage Refrigeration System, Freon Base Cold Storage Cooling System