Blast Chillers/Freezers use for cooling food quickly to a low temperature that is relatively safe from bacterial growth. Bacteria multiply fastest between +8 °C and +68°C. By reducing the temperature of cooked food from +70 °C to +3 °C within 90 minutes, the food is rendered safe for storage and later consumption. This method of preserving food is commonly used in food catering and in the preparation of ‘instant foods’ as it ensures the safety and the quality of the food product.

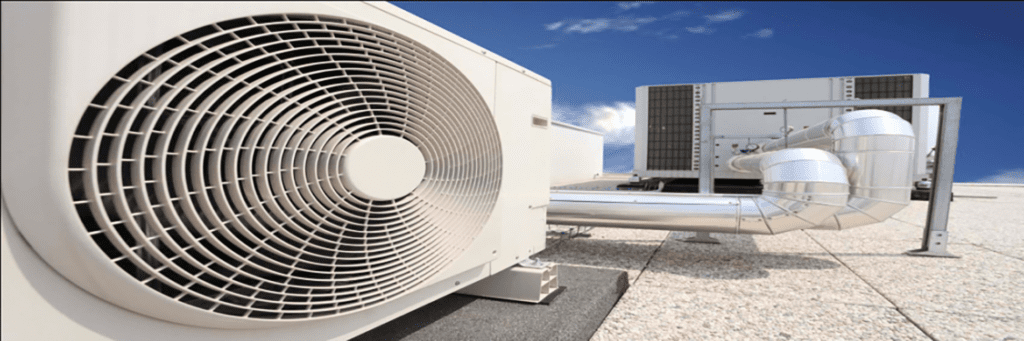

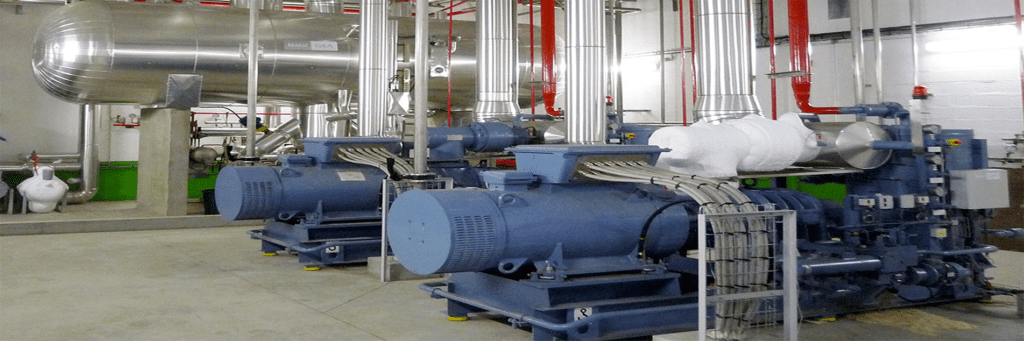

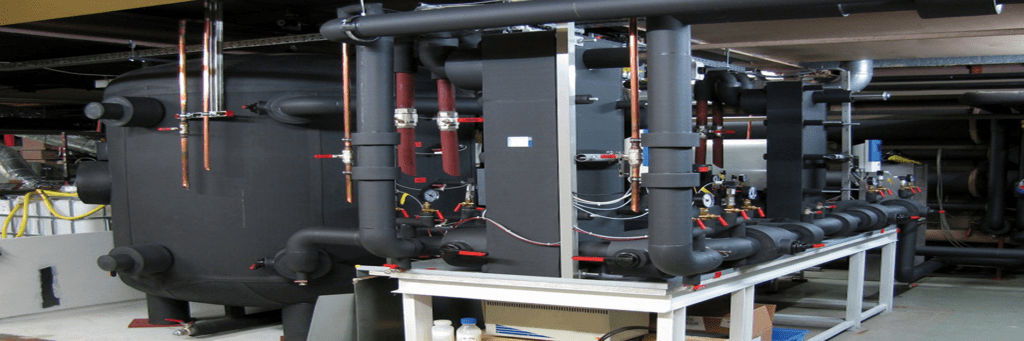

We, Hems Infratech Pvt. Ltd. are engaged in offering superior quality cold storage rooms and cold storage chambers. These rooms are designed and developed in accordance to customer’s needs and fabricated with modulated panels, insulated with injected polyurethane (PUF) or polystyrene foam (EPS). Every part and component used in these cold stores is of a top-quality and guaranteed to stand up under the most demanding conditions. Our cold stores are equipped with integrated Refrigeration equipments and Electronic system designed for better storage condition control and energy savings.

Specification:

The Blast Chill Refrigeration system is designed to quickly cool foods through the temperature danger zone most conducive to microorganism growth to assure food safety and quality. Rapid chilling also promotes increased product storage life and allows for greater labor productivity in the kitchen.

Standard Features:

- Microprocessor with 3 Food Probes

- On board Printer & Download Data Capability to PC with 72 Hour Memory

- Four Chilling Functions: * Blast Chill * Soft Chill * Flash Chill * Constant Chill

- Color Keyed Food Probes and Control System

- Automatic Hold Mode after Chilling Product

- Magnetic Door Gaskets & Door Handles

- Plasticized Fin Coil

- Rehingeable door (standard hinged left) with lock.

- Automatic or Manual Defrost

- ½ HP self-contained holding and 1¼ HP blast chill compressor

- Adjustable Product Chill Endpoints

- Adjustable Product Holding Temperature

Blast Chilling Operation:

In the Blast Chill mode, two blowers, as well as secondary temperature controls are in operation. Cabinet air temperature can be as low as 0°F. Close monitoring of temperature through the product probes assures rapid chilling without freezing the product. After chill operation is complete and food product has reached target temperature, the maintenance system takes over automatically and maintains the product at set maintenance temperature. Product temperature data is accumulated during operation and can be downloaded through a printout from the onboard printer. The control will store data for a 72 hour period.

Keywords:

Blast Chillers, Blast Freezers, Blast Chiller Unit, Blast Chiller for Cold Storage, Blast Freezing Unit, Blast Chillers Supplier, Blast Freezer Supplier, Cold Storage Blast Chiller, Industrial Blast Chiller, Commercial Blast Chillers, Commercial Blast Freezer, Industrial Blast Chiller Provider, Cold Storage Blast Chilling System, Cold Storage Blast Freezing System